Shape and size

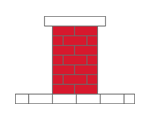

PILLAR CAP 24"

600mm x 600mm x 65mm

23 5/8" x 23 5/8" x 2 5/8"

PILLAR CAP 28½"

725mm x 65mm x 725mm

28 5/8" x 2 5/8" x 28 5/8"

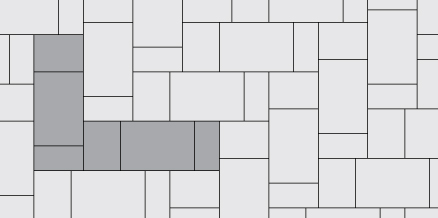

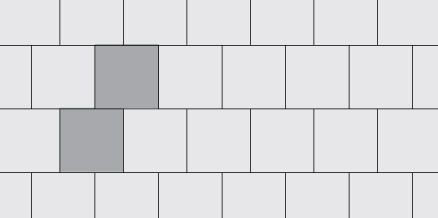

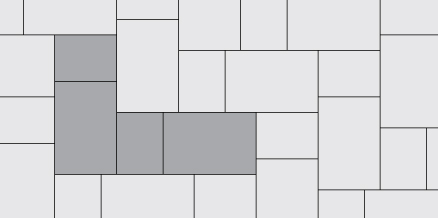

12"X24"

300mm x 600mm x 22mm

11 7/8" x 23 5/8" x 0 7/8"

12"X24"

300mm x 600mm x 22mm

11 7/8" x 23 5/8" x 0 7/8"

12"X24"

300mm x 600mm x 22mm

11 7/8" x 23 5/8" x 0 7/8"

12"X24"

300mm x 600mm x 22mm

11 7/8" x 23 5/8" x 0 7/8"

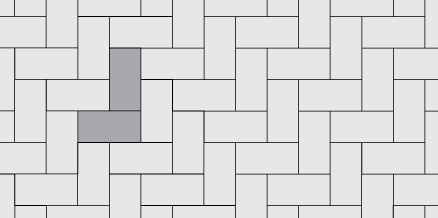

18"X24"

450mm x 600mm x 22mm

17 3/4" x 23 5/8" x 0 7/8"

18"X24"

450mm x 600mm x 22mm

17 3/4" x 23 5/8" x 0 7/8"

18"X24"

450mm x 600mm x 22mm

17 3/4" x 23 5/8" x 0 7/8"

18"X24"

450mm x 600mm x 22mm

17 3/4" x 23 5/8" x 0 7/8"

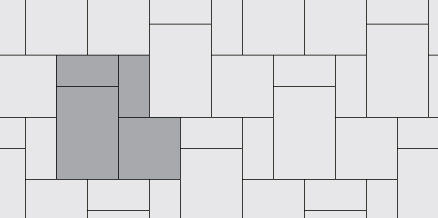

24"X24"

600mm x 600mm x 22mm

23 5/8" x 23 5/8" x 0 7/8"

24"X24"

600mm x 600mm x 22mm

23 5/8" x 23 5/8" x 0 7/8"

24"X24"

600mm x 600mm x 22mm

23 5/8" x 23 5/8" x 0 7/8"

24"X24"

600mm x 600mm x 22mm

23 5/8" x 23 5/8" x 0 7/8"

24"X36"

600mm x 900mm x 22mm

23 5/8" x 35 1/2" x 0 7/8"

24"X36"

600mm x 900mm x 22mm

23 5/8" x 35 1/2" x 0 7/8"

24"X36"

600mm x 900mm x 22mm

23 5/8" x 35 1/2" x 0 7/8"

24"X36"

600mm x 900mm x 22mm

23 5/8" x 35 1/2" x 0 7/8"

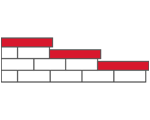

STEP 48"X16"

1,200mm x 150mm x 400mm

47 1/4" x 5 7/8" x 15 3/4"

STEP 48"X16"

1,200mm x 150mm x 400mm

47 1/4" x 5 7/8" x 15 3/4"

STEP 48"X16"

1,200mm x 150mm x 400mm

47 1/4" x 5 7/8" x 15 3/4"

STEP 72"X16"

1,830mm x 150mm x 400mm

72" x 5 7/8" x 15 3/4"

STEP 72"X16"

1,830mm x 150mm x 400mm

72" x 5 7/8" x 15 3/4"

STEP 72"X16"

1,830mm x 150mm x 400mm

72" x 5 7/8" x 15 3/4"

STEP 72"X16"

1,830mm x 150mm x 400mm

72" x 5 7/8" x 15 3/4"

COPING BULLNOSE

1,200mm x 50mm x 300mm

47 1/4" x 2" x 11 7/8"

COPING BULLNOSE

1,200mm x 50mm x 300mm

47 1/4" x 2" x 11 7/8"

COPING BULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING BULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING FULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING FULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,200mm x 50mm x 300mm

47 1/4" x 2" x 11 7/8"

COPING ROCK FACED

1,200mm x 50mm x 400mm

47 1/4" x 2" x 15 3/4"

COPING ROCK FACED

1,200mm x 50mm x 400mm

47 1/4" x 2" x 15 3/4"

COPING ROCK FACED

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,800mm x 50mm x 400mm

70 7/8" x 2" x 15 3/4"

COPING ROCK FACED

1,800mm x 50mm x 400mm

70 7/8" x 2" x 15 3/4"

COPING ROCK FACED

1,200mm x 50mm x 300mm

47 1/4" x 2" x 11 7/8"

COPING ROCK FACED

1,200mm x 50mm x 300mm

47 1/4" x 2" x 11 7/8"

COPING ROCK FACED

1,200mm x 50mm x 400mm

47 1/4" x 2" x 15 3/4"

COPING ROCK FACED

1,200mm x 50mm x 400mm

47 1/4" x 2" x 15 3/4"

COPING ROCK FACED

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,800mm x 50mm x 400mm

70 7/8" x 2" x 15 3/4"

COPING ROCK FACED

1,800mm x 50mm x 400mm

70 7/8" x 2" x 15 3/4"

PILLAR CAP 24"

600mm x 600mm x 65mm

23 5/8" x 23 5/8" x 2 5/8"

PILLAR CAP 28½"

725mm x 65mm x 725mm

28 5/8" x 2 5/8" x 28 5/8"

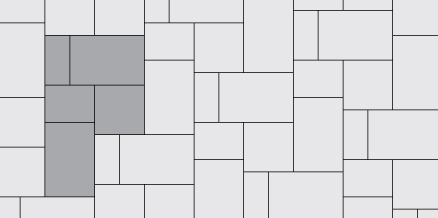

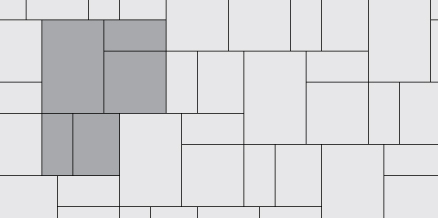

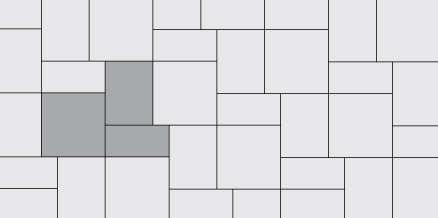

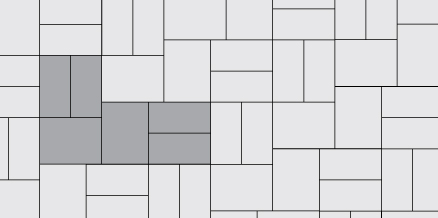

12"X24"

300mm x 600mm x 22mm

11 7/8" x 23 5/8" x 0 7/8"

18"X24"

450mm x 600mm x 22mm

17 3/4" x 23 5/8" x 0 7/8"

24"X24"

600mm x 600mm x 22mm

23 5/8" x 23 5/8" x 0 7/8"

24"X36"

600mm x 900mm x 22mm

23 5/8" x 35 1/2" x 0 7/8"

STEP 48"X16"

1,200mm x 150mm x 400mm

47 1/4" x 5 7/8" x 15 3/4"

STEP 72"X16"

1,830mm x 150mm x 400mm

72" x 5 7/8" x 15 3/4"

COPING BULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING FULLNOSE

1,800mm x 50mm x 300mm

70 7/8" x 2" x 11 7/8"

COPING ROCK FACED

1,800mm x 50mm x 400mm

70 7/8" x 2" x 15 3/4"

12"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

18"X24"

440mm x 590mm x 38mm

17 3/8" x 23 1/4" x 1 1/2"

24"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

24"X36"

590mm x 890mm x 38mm

23 1/4" x 35" x 1 1/2"

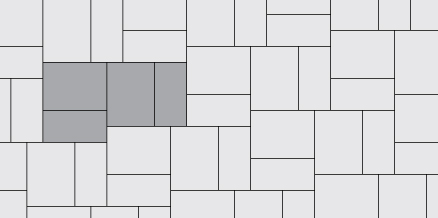

12"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

18"X24"

440mm x 590mm x 38mm

17 3/8" x 23 1/4" x 1 1/2"

24"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

24"X36"

590mm x 890mm x 38mm

23 1/4" x 35" x 1 1/2"

12"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

18"X24"

440mm x 590mm x 38mm

17 3/8" x 23 1/4" x 1 1/2"

24"X24"

590mm x 590mm x 38mm

23 1/4" x 23 1/4" x 1 1/2"

24"X36"

590mm x 890mm x 38mm

23 1/4" x 35" x 1 1/2"

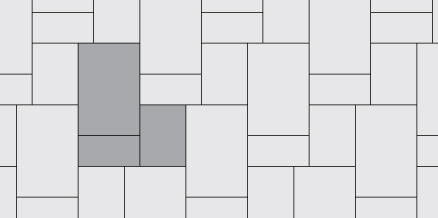

12"X24"

290mm x 590mm x 38mm

11 1/2" x 23 1/4" x 1 1/2"

18"X24"

440mm x 590mm x 38mm

17 3/8" x 23 1/4" x 1 1/2"

24"X24"

590mm x 590mm x 38mm

23 1/4" x 23 1/4" x 1 1/2"

24"X36"

590mm x 890mm x 38mm

23 1/4" x 35" x 1 1/2"

Download PDF

Download PDF  Email a copy

Email a copy