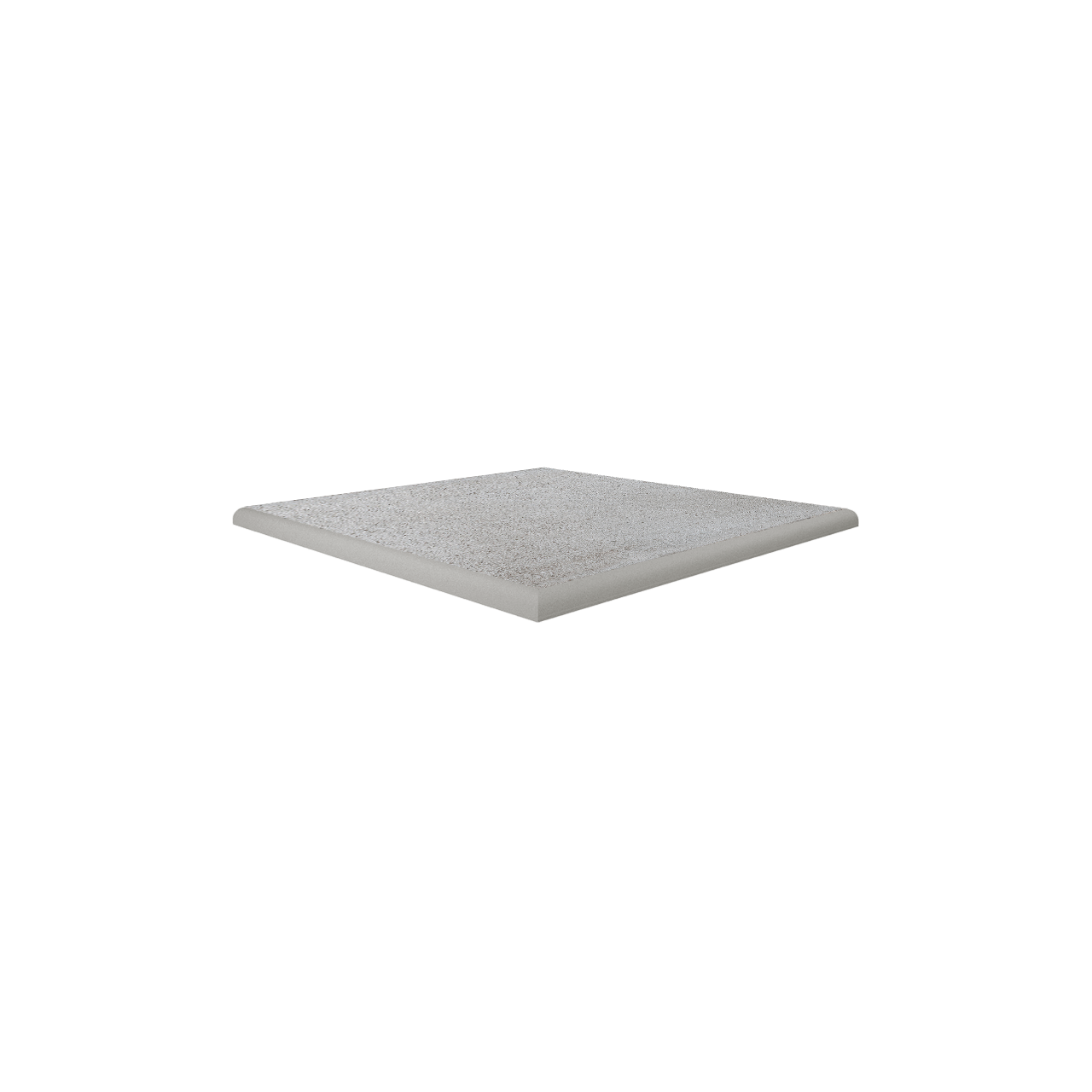

Porcelain is a thinly manufactured slab with sharp zero-bevel edges. Porcelain can be used residentially or commercially, but is not suitable for any vehicular applications. Porcelain can also be used in commercial roof deck pedestal applications where a thinner/lighter module is specified. Consult the project engineer for specific installation instructions for roof deck applications.

OVER CONCRETE INSTALLATION – Porcelain must be installed on a stable base. The best way to achieve this is to mortar the units on to a poured concrete pad - preferably a new concrete pad, although existing concrete can be used. It is recommended that you have a minimum 4” of ¾” crusher run gravel under the pad for support and drainage, (use any road base gravel in accordance with ASTM-D2940) compacted to 98% Standard Proctor Density (SPD).

Special Notes: Concrete Direct Overlay –

- Concrete integrity – concrete must be in good condition, and not crumbling

- Drainage slope – concrete below must be sloped away from all buildings and structures

- Base drainage - the area below the concrete must not be subject to frost movement

- Jointing – Exterior Grade Porcelain grout.

ALTERNATIVE PERMEABLE BASE – Porcelain may also be installed on a permeable base in climates with little or no freeze-thaw ground movement.

Use a min. 6” – 8” of ¾“ clear open-graded stone compacted to achieve full particle lock-up and consolidation. (Clear open-graded does not compact but does consolidate slightly by rattling the particles together.)

ALTERNATIVE PERMEABLE BEDDING COURSE – 1” thick of 1/8” clear open-graded chip stone – (ASTM No. 8 or 9) screeded over base.

ALTERNATIVE high density foam BASE

Products such as Gatorbase or other high-density foam products designed for exterior paving applications can also be used for porcelain installation. In this instance, the tiles sit directly on the foam base material. This eliminates compaction and it eliminates the need for joint grouting a small plastic tab is used to separate the units and keep them from touching each other.

These foam products can be used to replace a substantial portion of the gravel required below the surface but not eliminate it completely. It is recommended that you have a minimum 4” of ¾” crusher run gravel under the pad for support and drainage, (use any road base gravel in accordance with ASTM-D2940) compacted to 98% Standard Proctor Density (SPD).

HANDLING – Exercise caution when handling this product, as contact between its zero-bevel edges may cause damage.

EDGE RESTRAINT – not required when installed over concrete. Use manufacturer’s edge restraint system for high density foam installation.

CLEANERS – Porcelain cleans with simple soap and water.

caution – Porcelain can be slippery when wet.

Download PDF

Download PDF  Email a copy

Email a copy