Shape and size

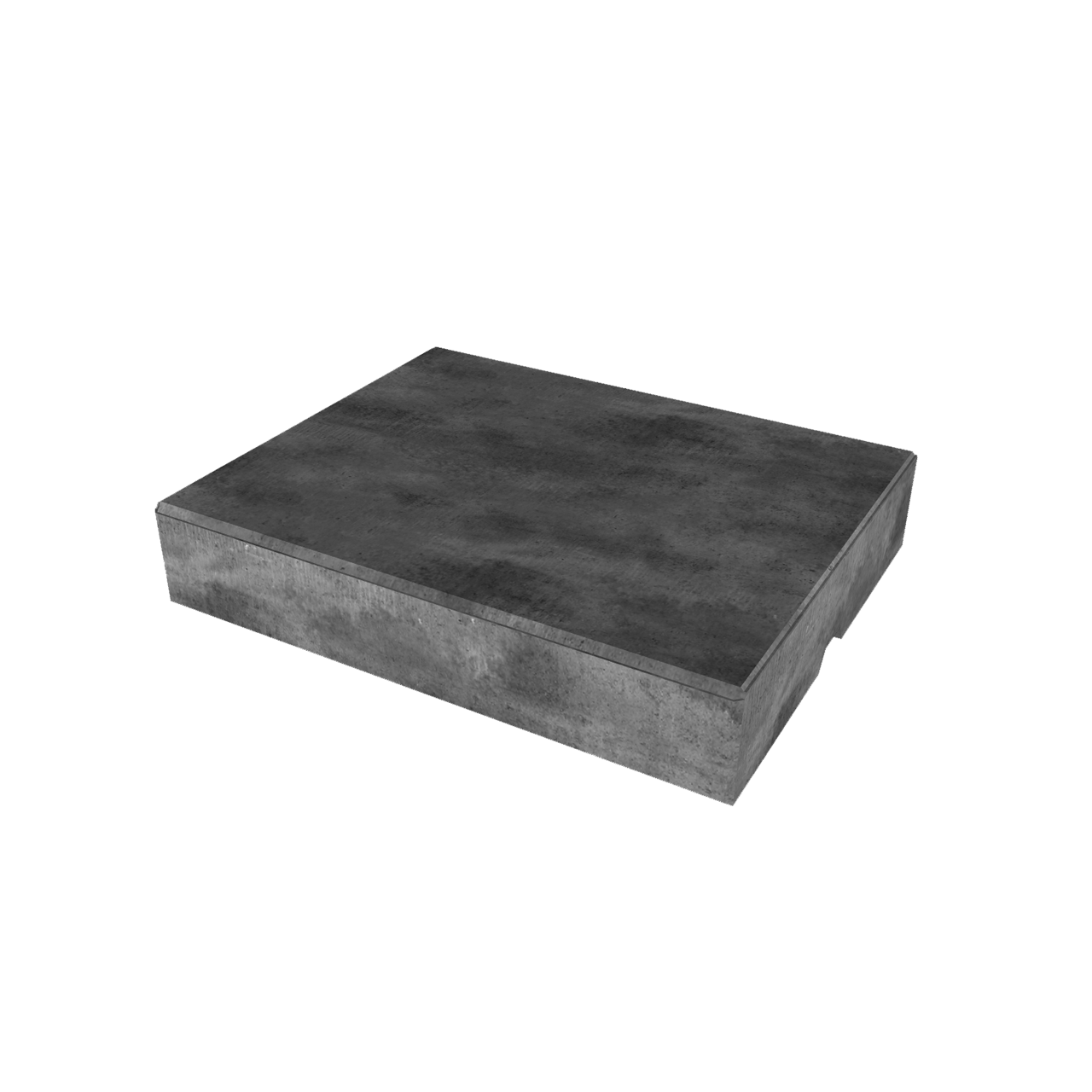

COPING

400mm x 75mm x 325mm

15 3/4" x 3" x 12 7/8"

COPING

400mm x 75mm x 325mm

15 3/4" x 3" x 12 7/8"

COPING

400mm x 75mm x 325mm

15 3/4" x 3" x 12 7/8"

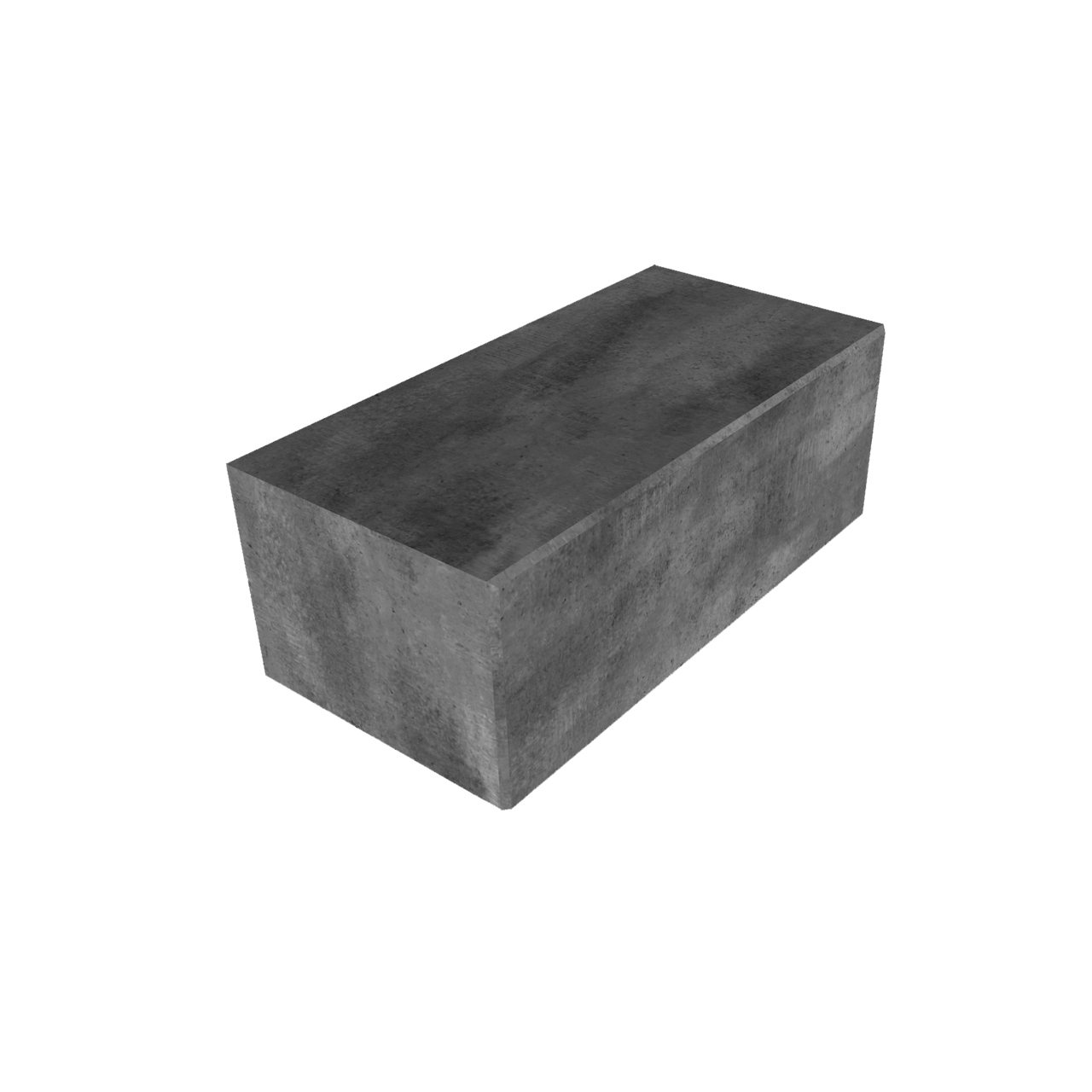

CORNER

400mm x 150mm x 200mm

15 3/4" x 5 7/8" x 7 7/8"

CORNER

400mm x 150mm x 200mm

15 3/4" x 5 7/8" x 7 7/8"

CORNER

400mm x 150mm x 200mm

15 3/4" x 5 7/8" x 7 7/8"

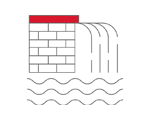

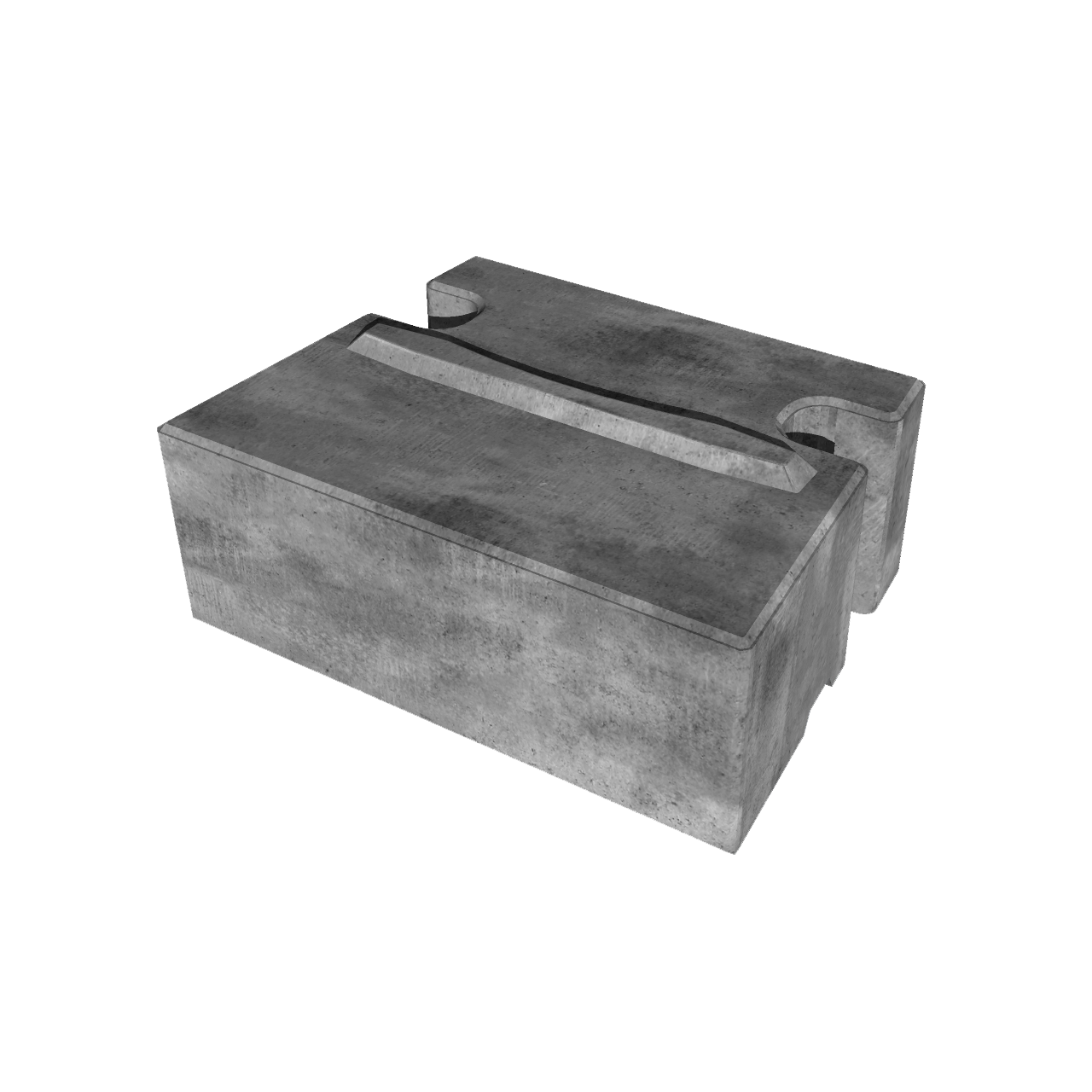

XL TAPERED

400mm x 150mm x 300mm

15 3/4" x 5 7/8" x 11 7/8"

XL TAPERED

400mm x 150mm x 300mm

15 3/4" x 5 7/8" x 11 7/8"

XL TAPERED

400mm x 150mm x 300mm

15 3/4" x 5 7/8" x 11 7/8"

COPING

400mm x 75mm x 325mm

15 3/4" x 3" x 12 7/8"

CORNER

400mm x 150mm x 200mm

15 3/4" x 5 7/8" x 7 7/8"

XL TAPERED

400mm x 150mm x 300mm

15 3/4" x 5 7/8" x 11 7/8"