Increasing Profits Effortlessly! Optimized Design, Optimized Base, and Optimized Crew

If you feel like “optimizing your business” just sounds like more make-work, you may not be alone. Skilled landscape craftsmen, those who have built successful businesses and are ready to grow again, inevitably find themselves doing less of the work they love and more of the business tasks they don’t.

There’s no shortage of hand-wavy advice online – maybe too much – and worse still, it’s often generalized, failing to deal with the specific realities of the hardscaping industry. Yes, you’ve looked at ways to reduce overhead, shifted more labor into production, and analyzed your service portfolio to deprioritize low-margin jobs. But Googling for deeper solutions returns mostly vague advice delivered in eye-rolling platitudes. Not exactly inspired reading.

You need a roadmap for building both your revenue and your margins, a strategy that speaks to your business and the logistics of hardscaping. The point is reduced effort, bigger return on investment – solutions you can put in place rapidly, with minimal disruption, that provide next-level optimizations to take your business efficiency to new levels.

If you’ve read some articles here on the UTEC Idea Exchange before, you may already be familiar with some of the most powerful and simple prescriptions for optimizing your planning and estimating, upgrading to newer materials and methods, and supercharging the performance of even your best crews. Here, we take a streamlined look at what it takes to drive increased efficiencies and profits in the hardscape business.

Starting the Project Right

A simple miscalculation in the planning and bid phase can carry right through the rest of the project, and sometimes no amount of effort is sufficient to get things back on track. Covering costs out of pocket isn’t part of your business model.

But it’s not like you’re new at this, and mistakes in planning are part of the risk. Anyway, your finely tuned spreadsheets are pretty good, and when it comes to methodology, there isn’t much that’s new.

What is new is the next generation of planning and estimating software. Whether you’re tech-savvy or not, you’ll be pleasantly surprised by the most recent generation of software – it’s easier to learn and use, smarter, more reliable, and in many cases more tightly focused on specialty businesses like yours.

We’re not talking about one-size-fits-all contracting applications. We mean software that is built specifically for landscaping and hardscaping, for your business, from the ground up.

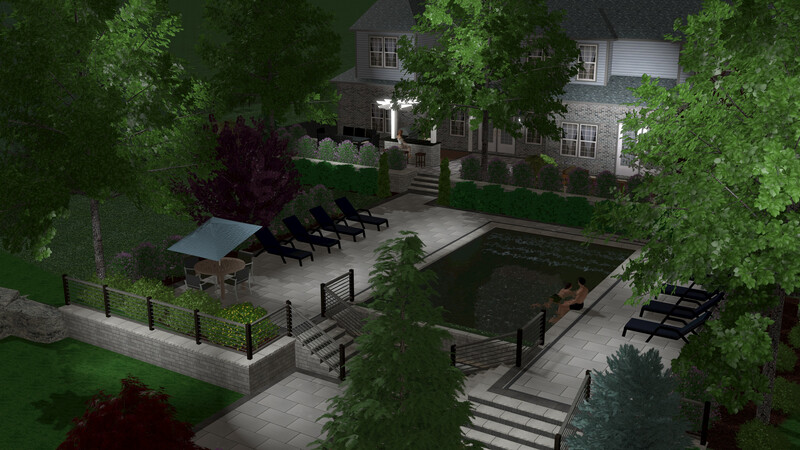

New technology makes planning and estimating a lot more fun than it sounds. Even inspiring. Uvision® from Unilock lets you and your client visualize your job in 3D from the start, from any angle, and gives you the option to fly-through the “finished” project, with realistic time-of-day lighting and textures that match the actual materials in your design.

Designing a job in software like Uvision® with simple point-and-click actions can also help reveal potentially costly issues before you spend a dime on materials. Plus, the visuals promote customer buy-in, reaffirm the designer’s vision, and, in turn, help mitigate the “I thought you were going to do such and such” syndrome at customer sign-off.

There’s also the immediate time pressure after that initial consultation – customers are likely chomping at the bit to get your estimate ASAP. The right application can not only decrease your turnaround time, it can provide exacting job costs and help extend your margins.

Learn more about Uvision® here!

New Materials and Methods

If you’re still using the identical materials and techniques you were even just three years ago, it’s worth looking at some recent updates to both. As you know, labor costs are a huge driver of project overruns, and time on the jobsite – especially idle time – burns into your margin. But not every factor that drives labor costs is obvious.

Experienced contractors have their favorite methods, favorite suppliers, and a preferred crew. They know exactly what works because the processes and materials they’ve always used have proven successful repeatedly. They’re not necessarily focused on fixing things that aren’t broken. The good news is that there are some recent meaningful improvements in installation techniques and materials specific to hardscaping that can have a real impact on your bottom line.

Most notably, base and bedding materials and installation techniques have evolved for the better. If you haven’t looked into new methods such as using open-graded base material for paver installations or new innovative products such as U-Cara, consider the possibility that you’re not just missing out on a new fad, you’re working harder and longer than necessary.

New materials and processes result in installations that install faster, are less hospitable to weed growth and insects, and are workable in all climates, ensuring a high-quality and durable result. But the hidden benefit? Labor costs. Installation is simply faster. Less time on site means lower labor costs.

Unilock provides direct assistance and training to their contractor community, helping you streamline and update your base installation processes, and, ultimately, reduce your labor costs.

Elevating Your Team

Then there’s the team.

If you’re happy with your crew, if they know their stuff and continue to learn and grow, they may not be on your radar as a candidate for optimization. Especially if you built your crew yourself, instilled in them the right attitudes and skills, and trust them to contribute to your profits – what’s left to optimize?

Two key targets of opportunity for inspiring greater labor efficiency are easily overlooked, especially if your team is already performing well.

The first is financial incentive. No matter how much integrity an employee has or how good their intentions are, there’s nothing like having skin in the game. A well thought-out incentive plan can help attract the best available labor in tight markets, and, designed correctly, incentives for per-project profits can be win-win, simultaneously building buy-in of employees and increasing profits. Monetary incentives can be offered for the efforts that benefit your bottom-line the most: recruiting new talent, on the job performance that leads to project success, or even re-hiring.

By including your crew in the spoils of victory, you’re not just providing a monetary reward, you’re sending a message that they’re appreciated and they’re valuable. Combined, the money and the gesture have motivating power that few other options do.

The second opportunity to empower your crew is investment in new equipment. Newer equipment such as the UniLyft by Unilock can speed up job completion and pay for itself in efficiency and reliability. The costs of having your crew stand around on the clock while equipment is repaired or replaced can creep into a project incrementally, and destroy project margins.

For your investment in monetary incentives and equipment, the devil is in the details. Or, in this case, the numbers. The numbers will tell a specific story about the ROI behind every option, and your primary equipment supplier can often help make the business case for the right course of action.

Summary

If you haven’t looked at the best planning software recently, refreshed your knowledge of the latest base materials and techniques, or checked out cutting-edge installation equipment, take a few moments to look at the related articles listed below. They’re here in the UTEC Idea Exchange and they get right to the point. It may be penny-pinching discipline and assiduous attention to detail that got you this far. But it’s worth taking a look at the latest and greatest periodically, if only to ensure that saving pennies isn’t costing you dollars.