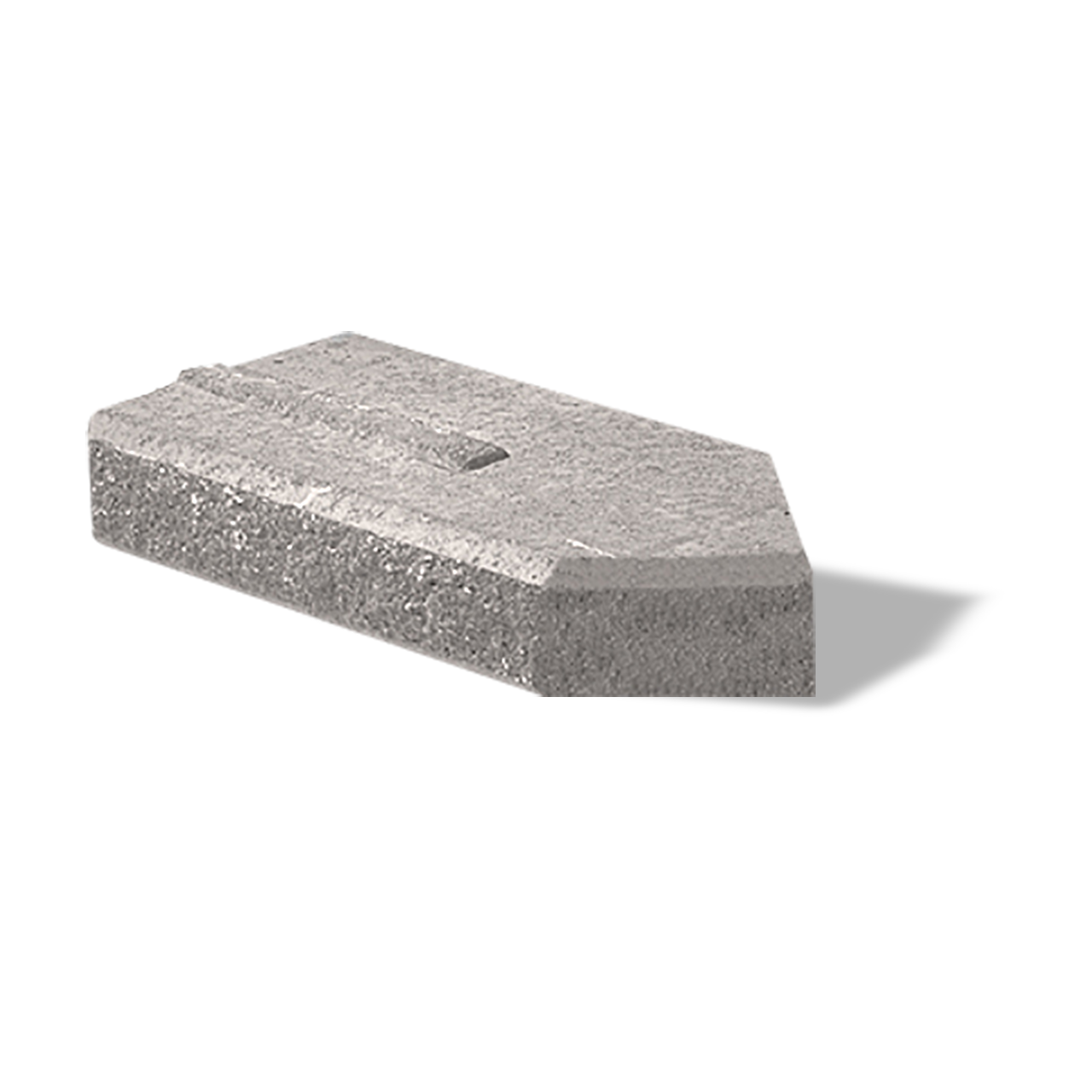

Shape and size

CORNER 45 DOUBLE

1,100mm x 185mm x 500mm

43 3/8" x 7 3/8" x 19 3/4"

CORNER 90 DOUBLE

1,100mm x 185mm x 500mm

43 3/8" x 7 3/8" x 19 3/4"

STANDARD 333"

1,200mm x 185mm x 333mm

47 1/4" x 7 3/8" x 13"

STANDARD 500"

1,200mm x 185mm x 500mm

47 1/4" x 7 3/8" x 19 3/4"

STANDARD 925"

1,200mm x 185mm x 925mm

47 1/4" x 7 3/8" x 36 1/2"

CORNER 45 DOUBLE

1,100mm x 185mm x 500mm

43 3/8" x 7 3/8" x 19 3/4"

CORNER 90 DOUBLE

1,100mm x 185mm x 500mm

43 3/8" x 7 3/8" x 19 3/4"

STANDARD 333"

1,200mm x 185mm x 333mm

47 1/4" x 7 3/8" x 13"

STANDARD 500"

1,200mm x 185mm x 500mm

47 1/4" x 7 3/8" x 19 3/4"

STANDARD 925"

1,200mm x 185mm x 925mm

47 1/4" x 7 3/8" x 36 1/2"