Installation Manual – For complete installation information, download the manual here.

Over Concrete Installation – Sandstone must be installed on a stable base. The best way to achieve this is to mortar the units on to a poured concrete pad - preferably a new concrete pad, although existing concrete can be used. It is recommended that you have a minimum 4” of ¾” crusher run gravel under the pad for support and drainage, (use any road base gravel in accordance with ASTM-D2940) compacted to 98% Standard Proctor Density (SPD).

Special Notes: Concrete Direct Overlay –

- Concrete integrity – concrete must be in good condition, and not crumbling

- Drainage slope – concrete below must be sloped away from all buildings and structures

- Base drainage - the area below the concrete must not be subject to frost movement

- Jointing – Mortar joint recommended

Alternative Permeable Base – Sandstone may also be installed on a permeable base.

Min. 6” – 8” of ¾“ clear open-graded stone compacted to achieve full particle lock-up and consolidation. (Clear open-graded does not compact but does consolidate slightly by rattling the particles together.)

Alternative Permeable Bedding Course – 1” thick of 1/8” clear open-graded chip stone – (ASTM No. 8 or 9) screeded over base.

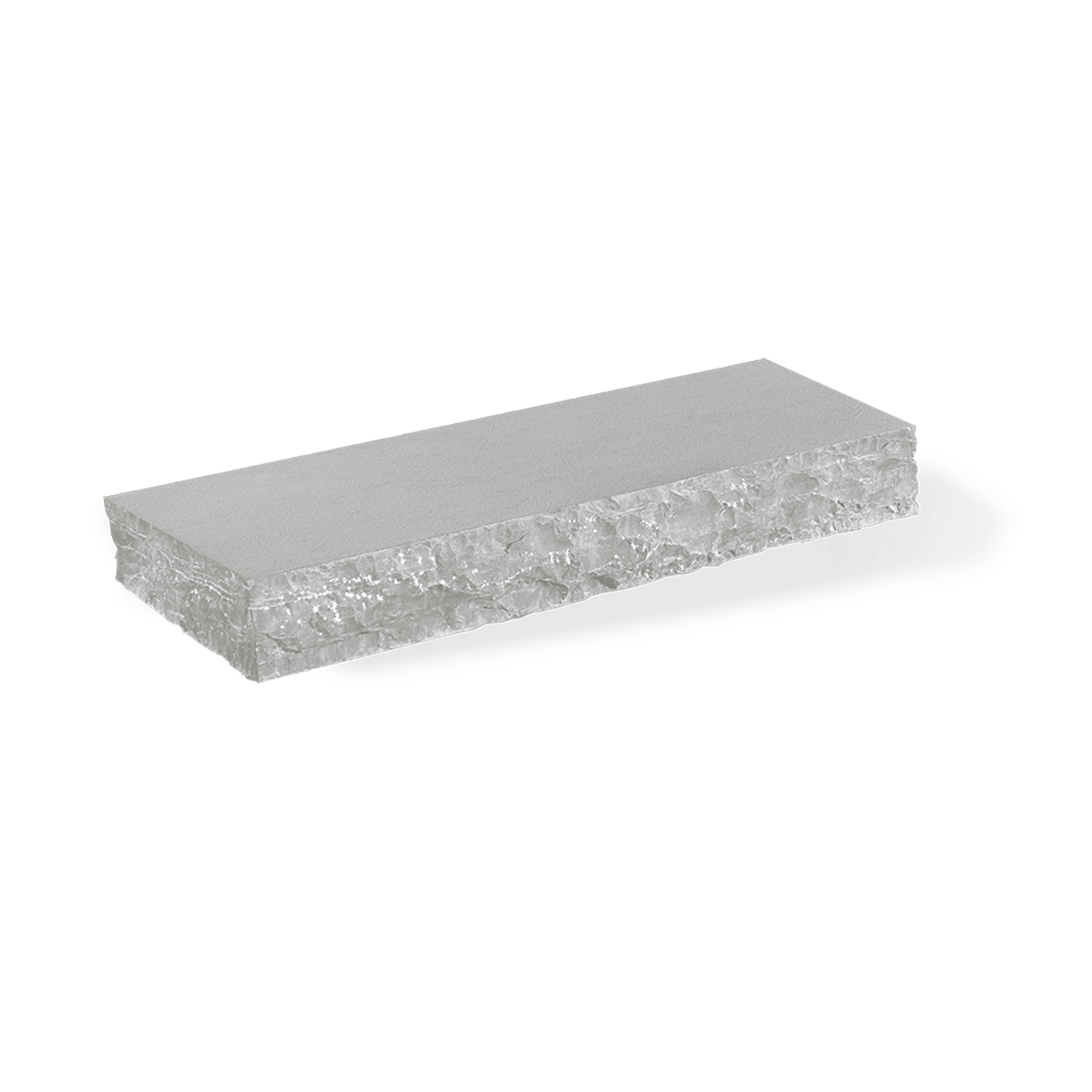

Water Proofing

- When installing over a concrete pad, waterproofing the sandstone and the concrete pad is an important procedure to prevent discoloration of the sandstone. A bond/slurry coat should be brushed onto the concrete pad prior to applying the mortar bedding. Apply the same bond coat to the backs of each sandstone unit before placing.

- When installing over a permeable base, you only need to apply the slurry coat to the back of the sandstone.

Handling – Exercise caution when handling this product, as contact between its zero-bevel edges may cause damage.

Edge Restraint - Always install an edge restraint around the perimeter of any paver installation not restrained by building structures. “Spike in” edge restraints come in plastic and various metals and work well for most applications. A concrete curb or a “sub-surface concrete wedge” can also be installed to retain the edge.

Cleaners – Unilock has partnered with United Stonecare, a UK company with over 30 years experience in the field of specialized cleaner and sealer products for natural stone. View products here: https://www.unicare-products.com/.