Shape and size

CORNER 90 LEFT

900mm x 300mm x 360mm

35 1/2" x 11 7/8" x 14 1/4"

CORNER 90 RIGHT

900mm x 300mm x 360mm

35 1/2" x 11 7/8" x 14 1/4"

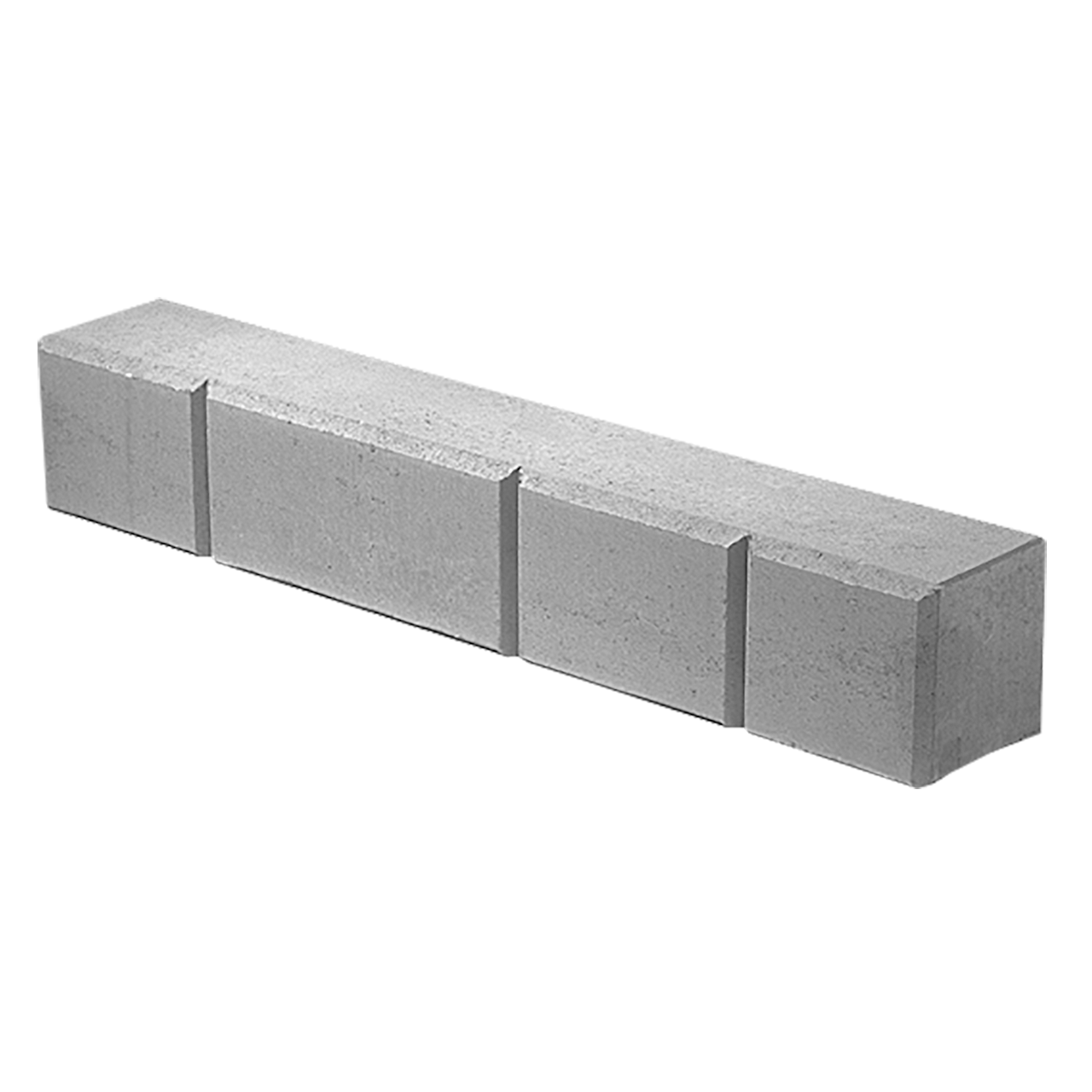

COPING CLOSED END

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"

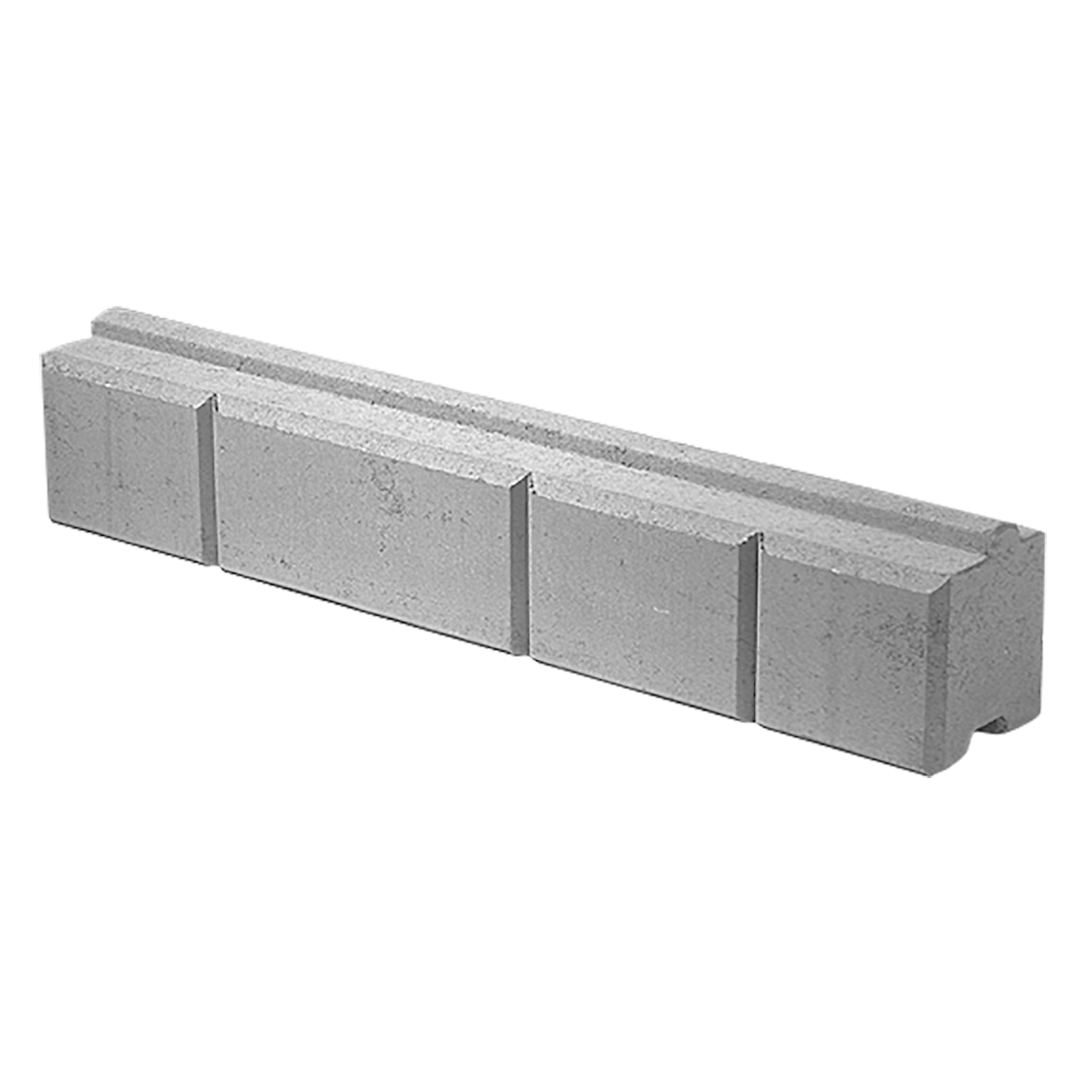

COPING STANDARD

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"

STANDARD

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"

CORNER 90 LEFT

900mm x 300mm x 360mm

35 1/2" x 11 7/8" x 14 1/4"

CORNER 90 RIGHT

900mm x 300mm x 360mm

35 1/2" x 11 7/8" x 14 1/4"

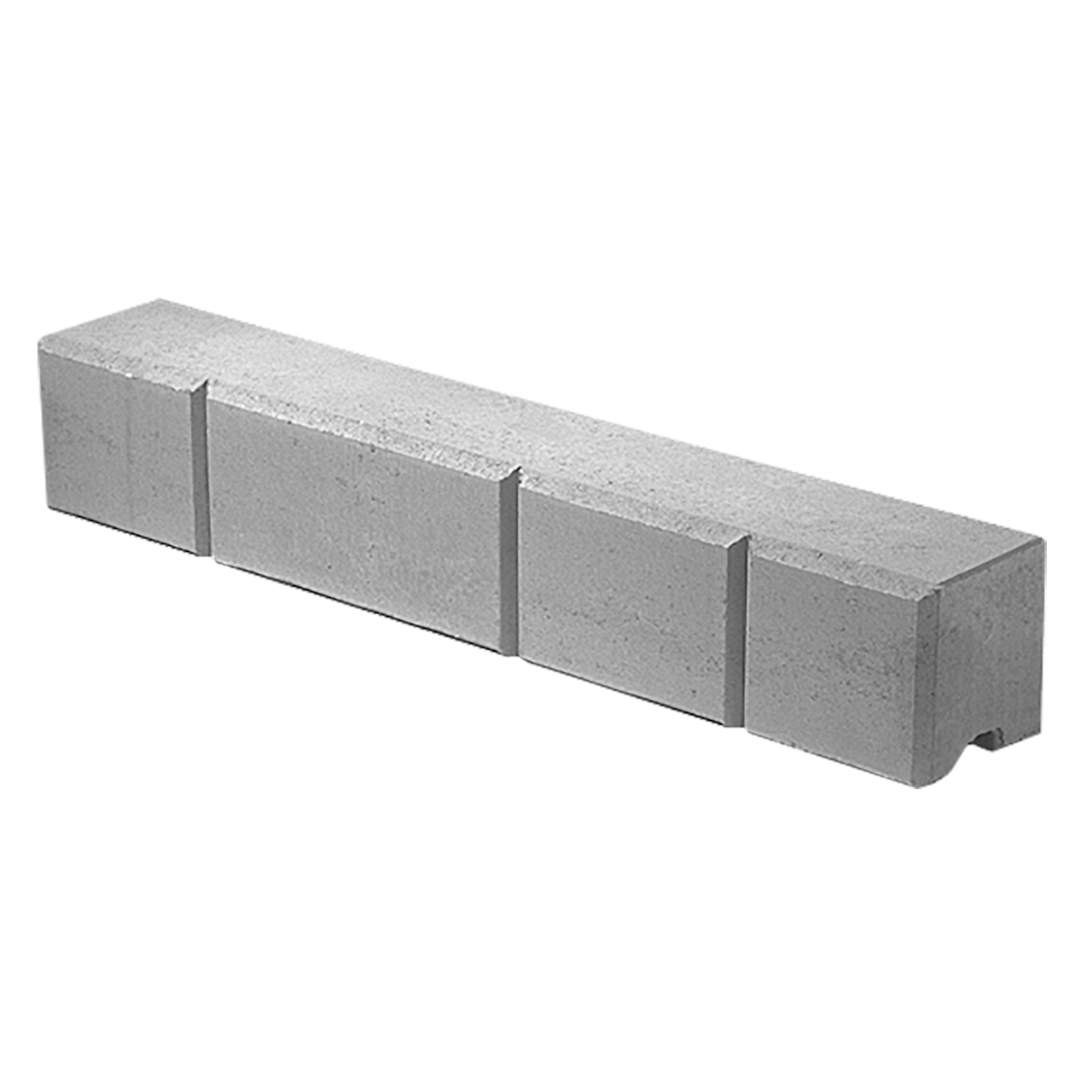

COPING CLOSED END

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"

COPING STANDARD

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"

STANDARD

1,830mm x 300mm x 360mm

72" x 11 7/8" x 14 1/4"