Edge Restraints: Why So Much Variety in Installation Methods?

All paver projects, regardless of size or type, have an important challenge to address—how to best restrain the edge of the pavers. Without a proper edge restraint, pavers will slowly move, leading to gaps and a breakdown of their interlocking system. Experienced hardscape contractors know this, but there’s divergence over what edge restraint material they should use. Here, we explore the pros and cons of the most popular materials.

The Options

While a variety of edge restraint options exist, two choices in particular go head-to-head for landscape contractors in terms of ease of use, affordability, and installation time: manufactured edge restraints and troweled concrete.

Manufactured Edge Restraints

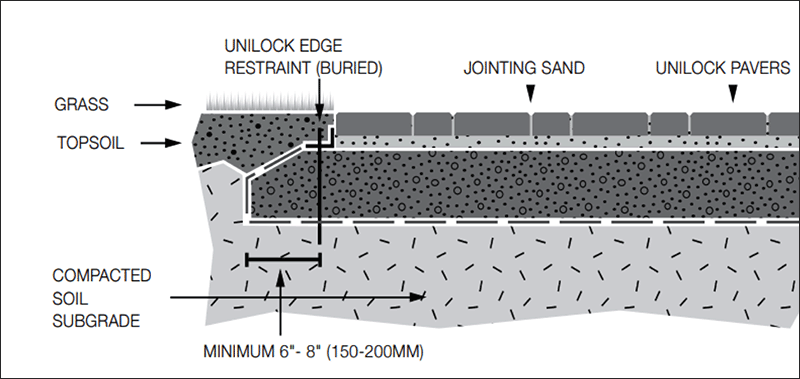

Forms of manufactured edge restraints include plastic, PVC, steel, and aluminum. These L-shaped strips of edging are held in place with spikes inserted into the base material. Unilock, together with the Interlocking Concrete Paver Institute (ICPI), recommends this method of edge restraint installation for a number of reasons. First, these systems are often considered “invisible” because they are installed below the finished paver. This allows for grass to grow and cover the restraint, as opposed to concrete, which is usually far from invisible.

Patrick Perugino, owner of Picture It Landscape & Design, prefers working with manufactured edge restraints in colder climates. They make the difference in the pavement’s ability to last through tough winters.

This method of edge restraint installation is also flexible, which can be quite useful for paver projects with curved designs. When working with a serpentine area, contractors can place the edge restraint, modify the material by snipping or bending, and nail it down. Also, the flexibility of the plastic edge restraint variation allows for more movement as the ground shifts over time, compared with troweled concrete’s very limited range of motion.

One of the potential downsides to using a manufactured edge restraint is the cost. Especially when working with larger hardscape projects, the price tag on plastic or metal edge restraint pieces can easily multiply. That’s when, Perugino suggests, contractors explain to clients the value that this type of edging brings to the project’s long-term performance.

Another debatable issue is the perception that manufactured edge restraints take up more installation time than a troweled concrete edge. Special materials that contractors don’t readily have on hand require slightly more time to order, and managing and storing the many pieces involved can be require a logistics adjustment. However, the paver project space would be available for use immediately after installation is complete, as opposed to troweled concrete, which must first be cured and needs at least another day to be ready for use.

Troweled Concrete

The other main edge restraint method that many landscape contractors stand by is the use of troweled concrete. Installing a concrete edge restraint was once considered the industry standard before manufactured edge restraints were introduced. For that reason, many seasoned landscape professionals feel more comfortable with this type of edge restraint installation.

In the troweled edge’s favor is concrete’s stability. Some professionals claim that the spikes or nails used in manufactured edge restraints could move or loosen due to ground heave. While many dispute such claims, some landscape contractors, particularly in the Northeast, stand by manufactured edge restraints in a variety of conditions.

The cheaper cost of concrete, especially for larger paver projects, is the overriding factor for its popularity among hardscape professionals. Price is more consistent, unlike the use of plastic or metal edge restraints, which can quickly add up in number.

Still, manufactured edge restraints come with a studied and standardized way of installation whereas troweled concrete edge restraints are not always installed in a consistent manner. Landscape professional Greg Ambrose says, “You can ask five different contractors for the right way to install a troweled concrete edge restraint, and they will give you six different answers!”

Concrete offers stability, but it’s not always able to meet the pressure of earth’s shifting movement. Heaving concrete can result in gaps between pavers.

Is There a Winner?

Recommended by Unilock and ICPI, manufactured edge restraints have gained favor in recent years with landscape professionals who work across a variety of weather and socioeconomic climates. Troweled concrete, however, continues to have backing by contractors who have experienced many successful installations with their favored material and methods.

Could a noticeable shift in preference occur if a more standard way of installing concrete edge restraints were put into place? Can the industry withstand multiple edge restraint installation practices long-term? Time will tell. In the meantime, it seems the most appropriate edge restraint approach to any one project truly depends on the installer’s preference and priorities, including timeliness, cost, and lasting value.