Veuillez appeler le 1-800-Unilock ou contacter l'un de nos responsables de territoire.

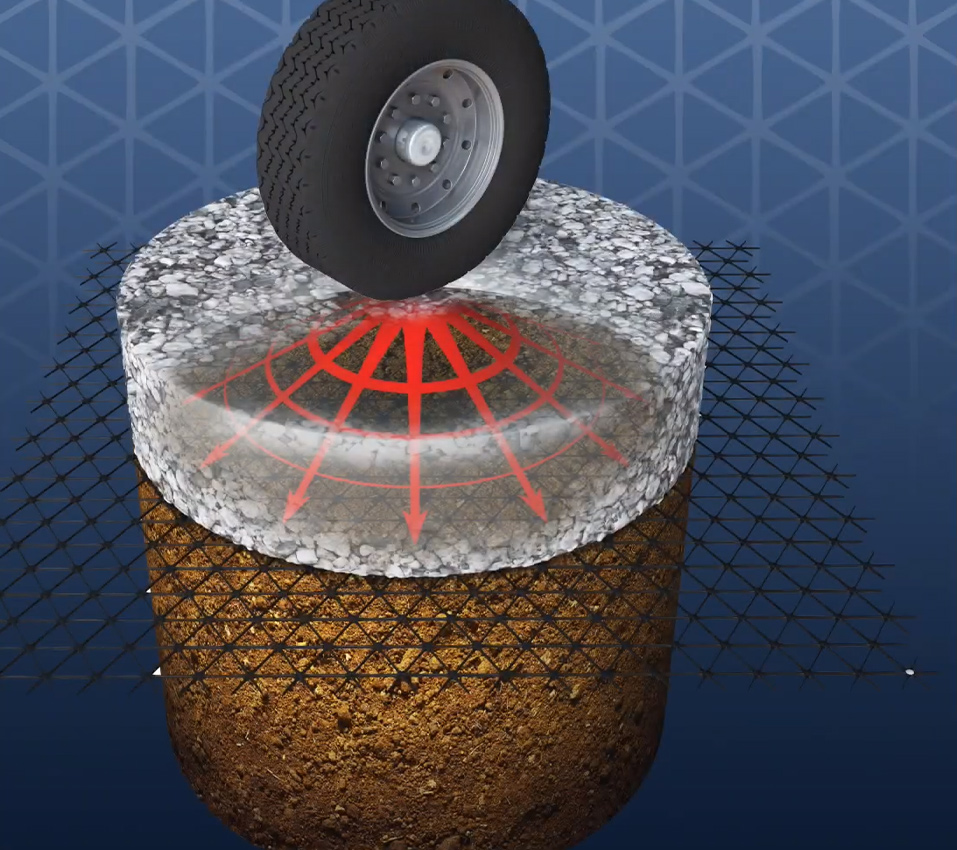

Unilock DriveGrid Geogrid is an advanced product specifically designed for trafficked surfaces. DriveGrid Geogrid’s multi-directional properties leverage triangular geometry, one of construction’s most stable and widely utilized shapes, to provide an enhanced level of in-plan stiffness. Its triangular structure, coupled with improved rib and junction geometry, offers the construction industry an improved alternative to conventional and practices.

DriveGrid Geogrid is manufactured from a punched polypropylene sheet oriented in multiple, equilateral directions to form its triangular apertures, resulting in high radial stiffness throughout the full 360 degrees. This feature yields a more efficient product that delivers optimal in-service stress transfer rom the aggregate to the stabilizing geogrid.